Properties and Overview of PEEK (Polyether Ether Ketone)

Overview:

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic polymer renowned for its exceptional strength, heat resistance, and chemical stability. As one of the most advanced engineering plastics available, PEEK is often used in applications where extreme conditions demand materials with superior performance. Its unique properties, including wear resistance, dimensional stability, and biocompatibility, make PEEK a preferred choice in the aerospace, medical, automotive, and electronics industries.

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic polymer renowned for its exceptional strength, heat resistance, and chemical stability. As one of the most advanced engineering plastics available, PEEK is often used in applications where extreme conditions demand materials with superior performance. Its unique properties, including wear resistance, dimensional stability, and biocompatibility, make PEEK a preferred choice in the aerospace, medical, automotive, and electronics industries.

Production:

The production of PEEK involves the polymerization of monomers like hydroquinone and 4,4'-difluorobenzophenone through nucleophilic substitution reactions in the presence of a solvent. This process creates a semicrystalline polymer with a rigid aromatic backbone and ether and ketone functional groups, contributing to its thermal and mechanical properties. PEEK can be processed using injection molding, extrusion, and compression molding, allowing manufacturers to create highly precise complex components. Its high-temperature stability and chemical resistance make it suitable for harsh processing environments.

Applications:

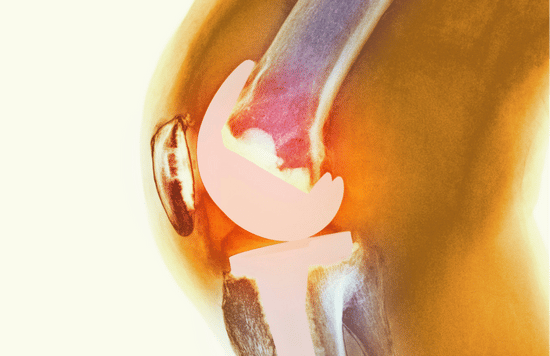

PEEK's applications span various industries due to its exceptional properties. In the aerospace sector, it is used for components such as bushings, brackets, and seals, where its lightweight nature and resistance to high temperatures ensure durability and efficiency. The medical field relies on PEEK for implants, surgical instruments, and dental devices due to its biocompatibility and ability to withstand sterilization processes. In the automotive industry, PEEK is employed in engine components, transmission parts, and electrical connectors, offering reliability in high-stress environments. Its chemical resistance and dielectric properties also make it valuable in electronics for insulating components and circuit boards. Additionally, PEEK is used in oil and gas applications, providing corrosion resistance and mechanical strength under extreme pressures and temperatures.

Summary:

Polyether Ether Ketone is a high-performance polymer that combines strength, thermal stability, and chemical resistance, making it a critical material for demanding applications. Its versatility and ability to perform in extreme environments ensure its ongoing importance in advanced engineering and manufacturing. As industries continue to push the boundaries of performance and sustainability, PEEK remains at the forefront of innovation, supporting cutting-edge solutions across various sectors.

See a comprehensive list of electrical, mechanical, physical and thermal properties for PEEK (Polyether Ether Ketone) below:

Electrical Properties of PEEK (Polyether Ether Ketone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of PEEK (Polyether Ether Ketone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of PEEK (Polyether Ether Ketone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of PEEK (Polyether Ether Ketone)

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

ALLOYS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!