Properties and Overview of Copper Alloy C101

Overview:

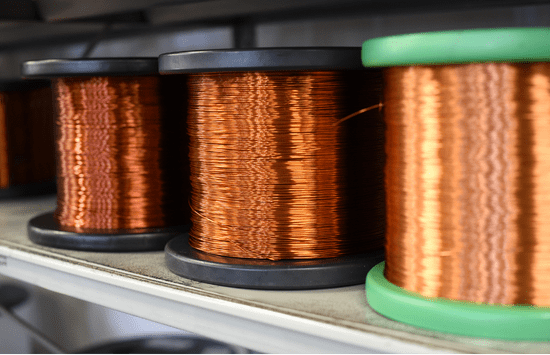

Copper Alloys are a critical component of modern industry, valued for their exceptional conductivity, corrosion resistance, and versatility. Combining copper with other elements such as zinc, tin, aluminum, or nickel creates a wide range of alloys, each tailored to specific applications. This adaptability has made copper alloys a cornerstone of traditional craftsmanship and cutting-edge engineering.

Copper Alloys are a critical component of modern industry, valued for their exceptional conductivity, corrosion resistance, and versatility. Combining copper with other elements such as zinc, tin, aluminum, or nickel creates a wide range of alloys, each tailored to specific applications. This adaptability has made copper alloys a cornerstone of traditional craftsmanship and cutting-edge engineering.

Production:

The production of copper alloys begins with the selection and combination of raw materials. Copper is melted with alloying elements in carefully controlled proportions to achieve the desired characteristics. The molten mixture is cast into ingots or billets, which are then processed into usable forms through rolling, extrusion, or forging techniques. Advances in metallurgical processes, including continuous casting and precision alloying, have further enhanced the quality and performance of copper alloys. Surface treatments, heat treatments, and other post-processing methods may also be applied to improve durability, machinability, or appearance.

Applications:

Applications of copper alloys span an extraordinary range of industries. In electrical engineering, copper’s unparalleled conductivity makes its alloys indispensable for wires, connectors, and electronic components. Brass, a prominent copper-zinc alloy, is widely used in plumbing, mechanical components, and decorative items due to its strength, corrosion resistance, and aesthetic appeal. Bronze, a copper-tin alloy, is revered for its durability and has applications in bearings, marine components, and artistic sculptures. Copper-nickel alloys, known for their excellent resistance to seawater corrosion, are commonly employed in shipbuilding, desalination plants, and offshore platforms. Additionally, copper alloys are used in coinage, musical instruments, and heat exchangers, where their combination of strength, malleability, and thermal conductivity proves invaluable.

The environmental benefits of copper alloys further enhance their significance. Copper and its alloys are highly recyclable, with a substantial proportion of production relying on recycled materials. This reduces the environmental impact of mining and extraction while conserving natural resources. Despite these advantages, challenges such as material cost and susceptibility to oxidation in specific environments drive ongoing research into protective coatings, advanced alloy formulations, and improved processing techniques.

Summary:

Copper alloys exemplify the fusion of tradition and innovation, offering properties that address the diverse needs of industries worldwide. From enhancing the efficiency of electrical systems to shaping timeless works of art, these alloys remain an essential material in both practical and creative domains. As sustainability and technological advancements continue to shape global priorities, copper alloys will remain vital in enabling progress and innovation across countless fields.

See a comprehensive list of electrical, mechanical, physical and thermal properties for Copper Alloy C101 below:

Electrical Properties of Copper Alloy C101

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Mechanical Properties of Copper Alloy C101

| Mechanical Property (Units) | Value |

|---|---|

| Copper Alloy C101 Compressive Strength (MPa) | ~200 |

| Copper Alloy C101 Ductile to Brittle Transition Temperature (°C) | Unknown |

| Copper Alloy C101 Fatigue Limit (MPa) | ~40 to 50 |

| Copper Alloy C101 Fracture Toughness (MPa·√m) | ~30 to 40 |

| Copper Alloy C101 Hardness Brinell | 45 to 60 |

| Copper Alloy C101 Hardness Rockwell | 30 to 35 HRB |

| Copper Alloy C101 Hardness Vickers | 50 to 70 |

| Copper Alloy C101 Heat Deflection Temperature (°C) | N/A - Not a Polymer |

| Copper Alloy C101 Modulus of Elasticity / Young's Modulus (GPa) | 110 to 128 |

| Copper Alloy C101 Percent Elongation (%) | 35 to 50 |

| Copper Alloy C101 Poissons Ratio | 0.34 |

| Copper Alloy C101 Shear Modulus (GPa) | 45 |

| Copper Alloy C101 Shear Strength (MPa) | 150 to 180 |

| Copper Alloy C101 Ultimate Tensile Strength (MPa) | 210 to 250 |

| Copper Alloy C101 Yield Strength (MPa) | 70 to 100 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Physical Properties of Copper Alloy C101

| Physical Property (Units) | Value |

|---|---|

| Copper Alloy C101 Boiling Point at Atmospheric Pressure (°C) | Unknown |

| Copper Alloy C101 Chemical Composition (Element %) | Cu ≥ 99.99% |

| Copper Alloy C101 Cost ($/kg) | 8 to 12 |

| Copper Alloy C101 Density at 'Standard Temperature and Pressure' (kg/m3) | 8940 |

| Copper Alloy C101 Glass Transition Temperature at Atmospheric Pressure (°C) | N/A - Not a Polymer |

| Copper Alloy C101 Melting Point at Atmospheric Pressure (°C) | 1085 |

| Copper Alloy C101 Polymer Family | N/A - Not a Polymer |

| Copper Alloy C101 Refractive Index | Unknown |

| Copper Alloy C101 Specific Gravity | 8.94 |

| Copper Alloy C101 Viscosity at Melting Point (mPa·s) | 3 to 4 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

Thermal Properties of Copper Alloy C101

| Thermal Property (Units) | Value |

|---|---|

| Copper Alloy C101 Coefficient of Thermal Expansion (µm/m·K) | 16.6 |

| Copper Alloy C101 Emissivity Coefficient | 0.15 to 0.20 |

| Copper Alloy C101 Specific Heat Capacity (J/kg·K) | 385 |

| Copper Alloy C101 Thermal Conductivity (W/m.K) | 386 |

| Copper Alloy C101 Thermal Conductivity (BTU/h·ft·°F) | 223.18 |

Unfamiliar with a property? Click it's description to be given a full definition in the GLOSSARY

See properties and overview for

POLYMERS and CHEMICAL ELEMENTS

popular in engineering

Require different units not displayed?

CONVERT VARIOUS UNITS HERE

ADDED TO MY FAVORITES!

ADDED TO MY FAVORITES! REMOVED FROM MY FAVORITES!

REMOVED FROM MY FAVORITES!